This article summarises the results of the paper “Organized complexity of digital business strategy: a configurational perspective“, written by Y. Park and S. Mithas, published by MIS Quartely in 2020.

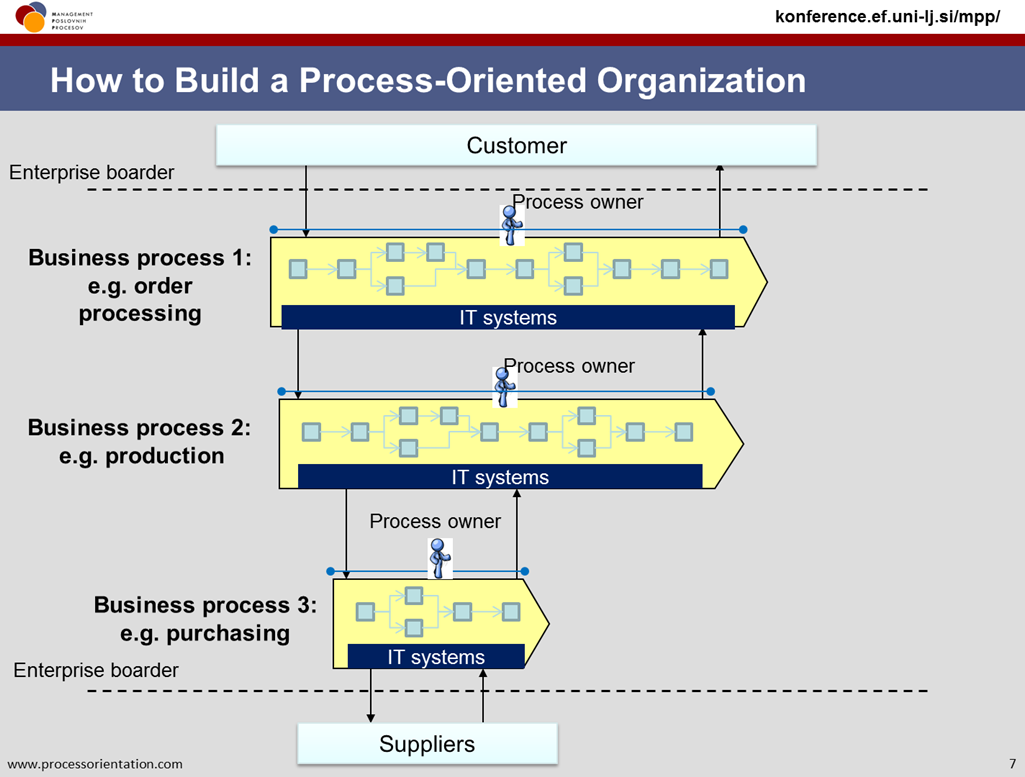

The paper addresses the issue of how firms should configure organizational capabilities to achieve competitive advantage in digital environments. Digital business strategy consists of several organizational capabilities, digital and non-digital, listed below, that work together to influence the firm’s competitiveness.

- Leadership (including how senior leaders set and deploy organizational values, short- and longer-term directions, etc.)

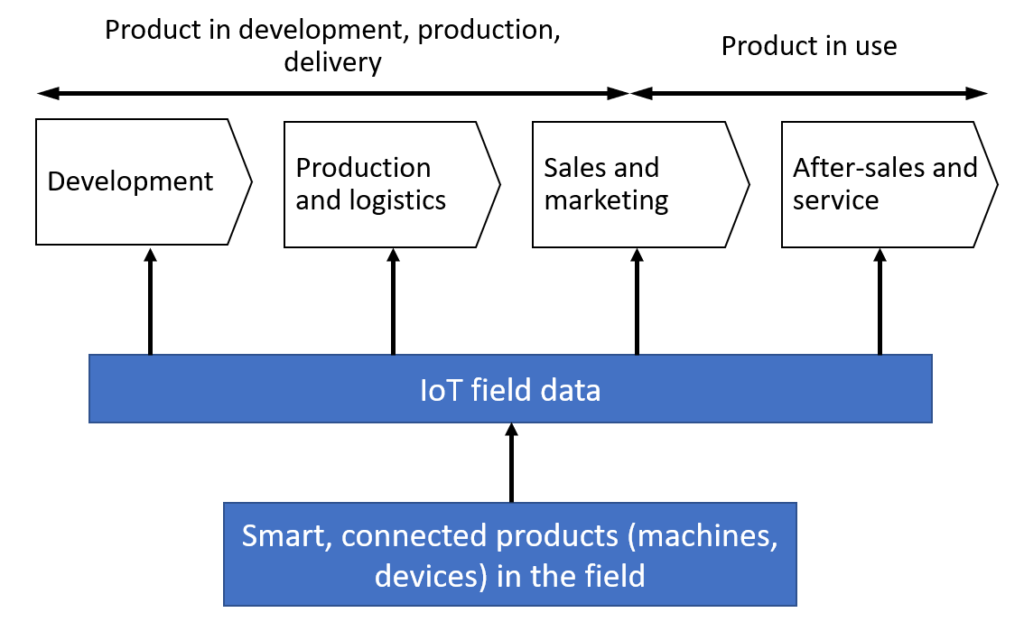

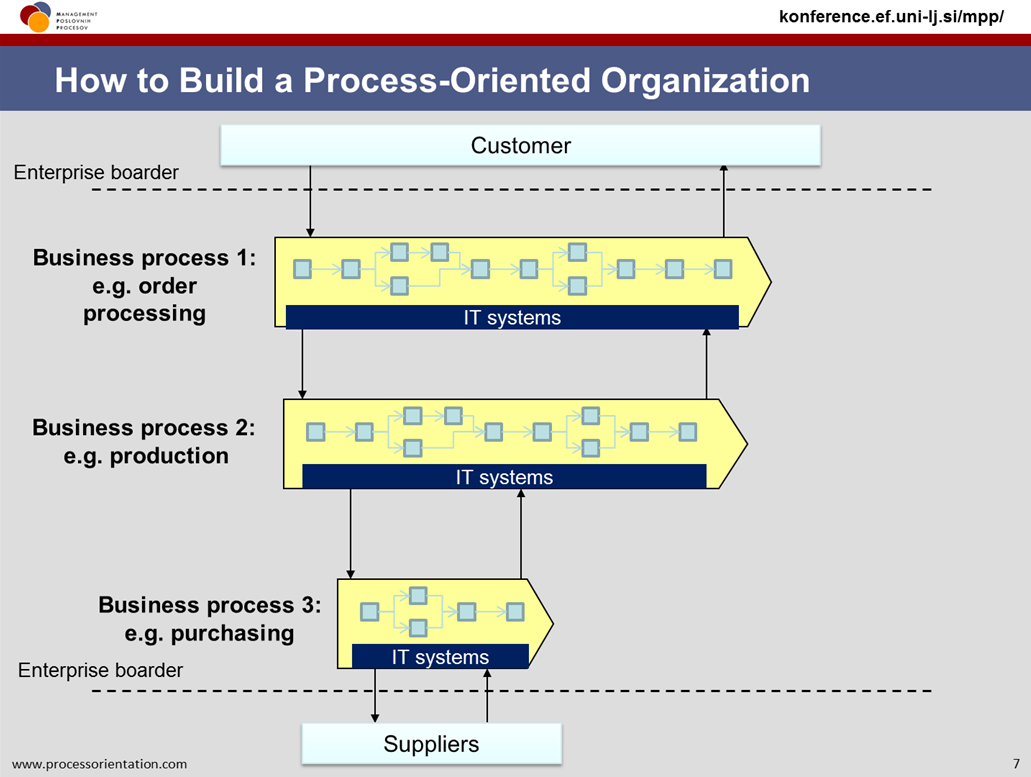

- IT-enabled information analytics (including data availability, reliable and user-friendly systems, etc.)

- Strategic planning (including the strategy development process, strategic objectives and the timetable for achieving them)

- Customer focus (how the organisation identifies the needs and preferences of customers and markets to ensure the continued relevance of the products/services offered and to develop new opportunities).

- HR focus (formal and informal mechanisms of employee motivation, effective communication and knowledge/skills sharing, effective succession planning for senior leadership, etc.)

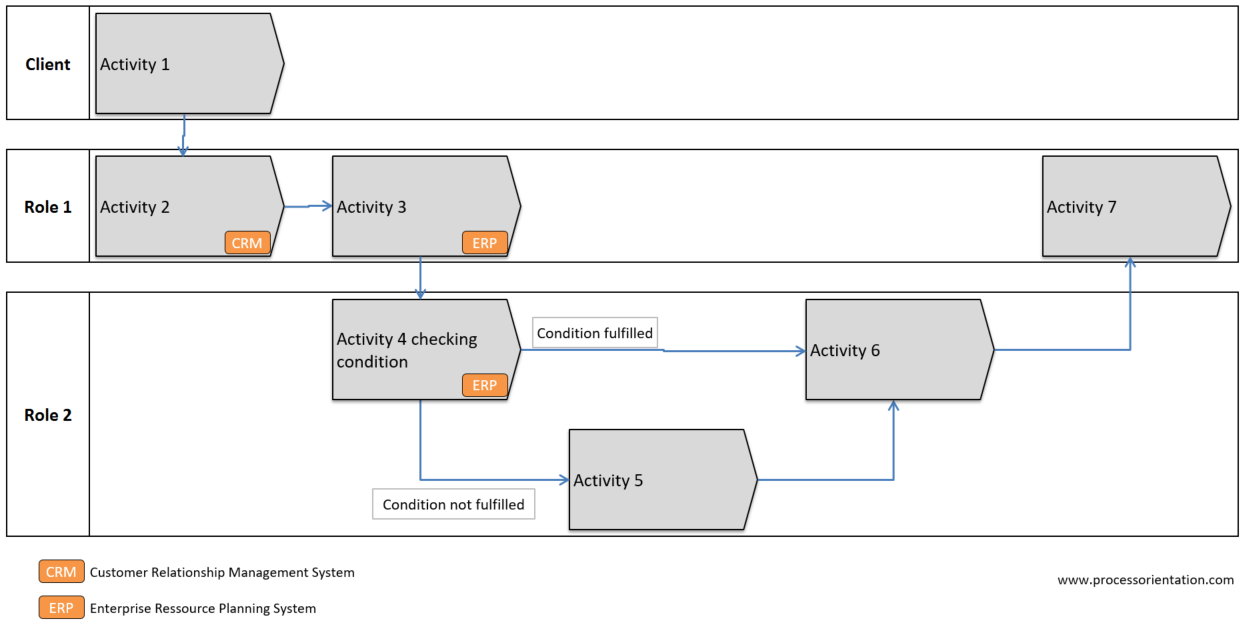

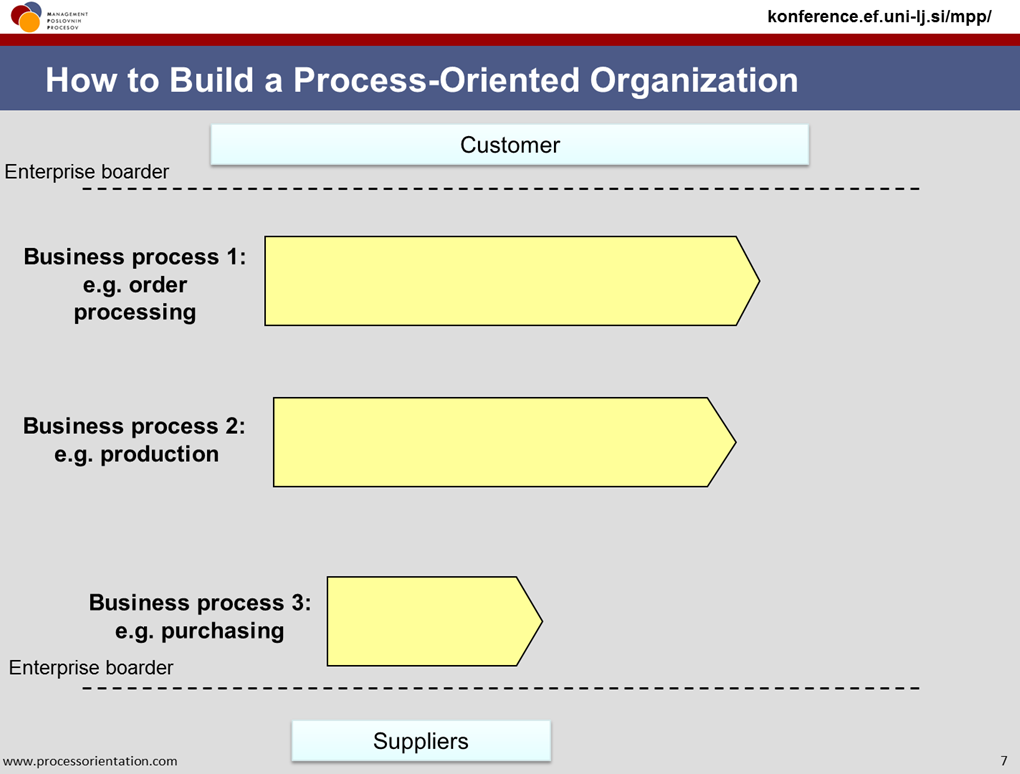

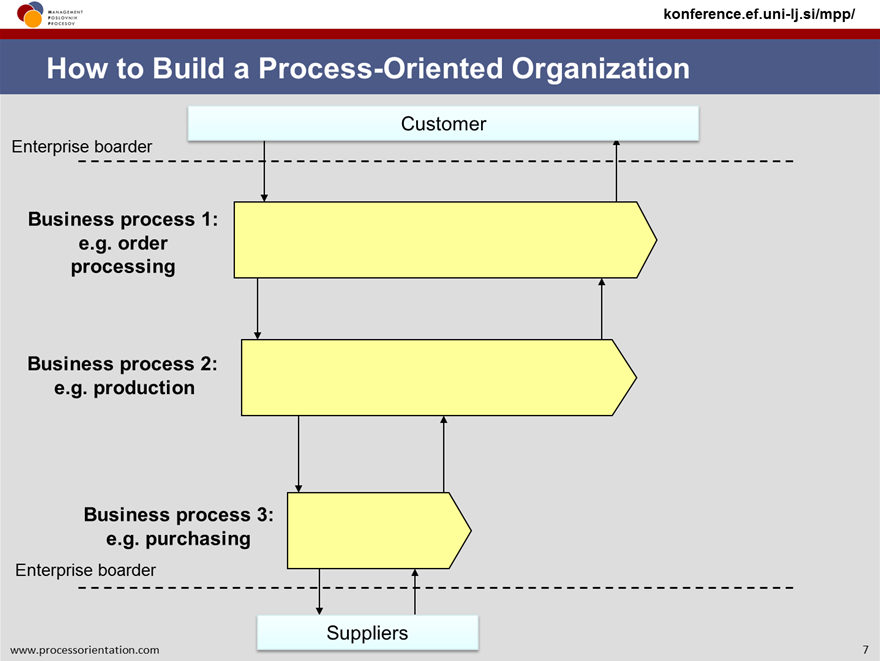

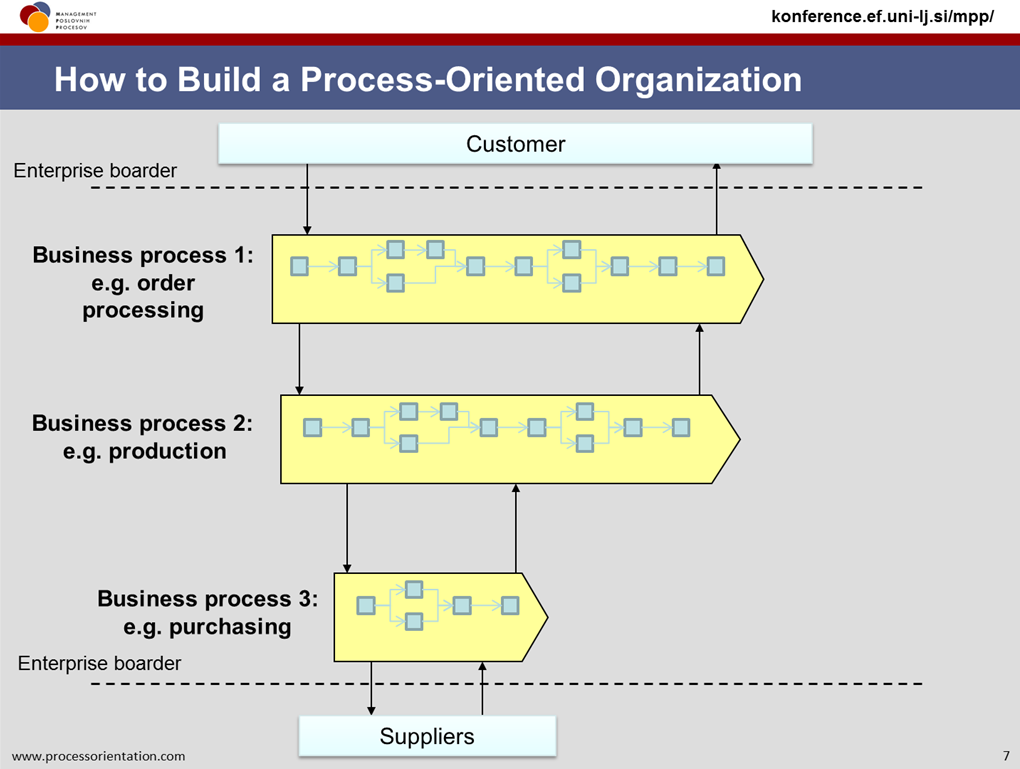

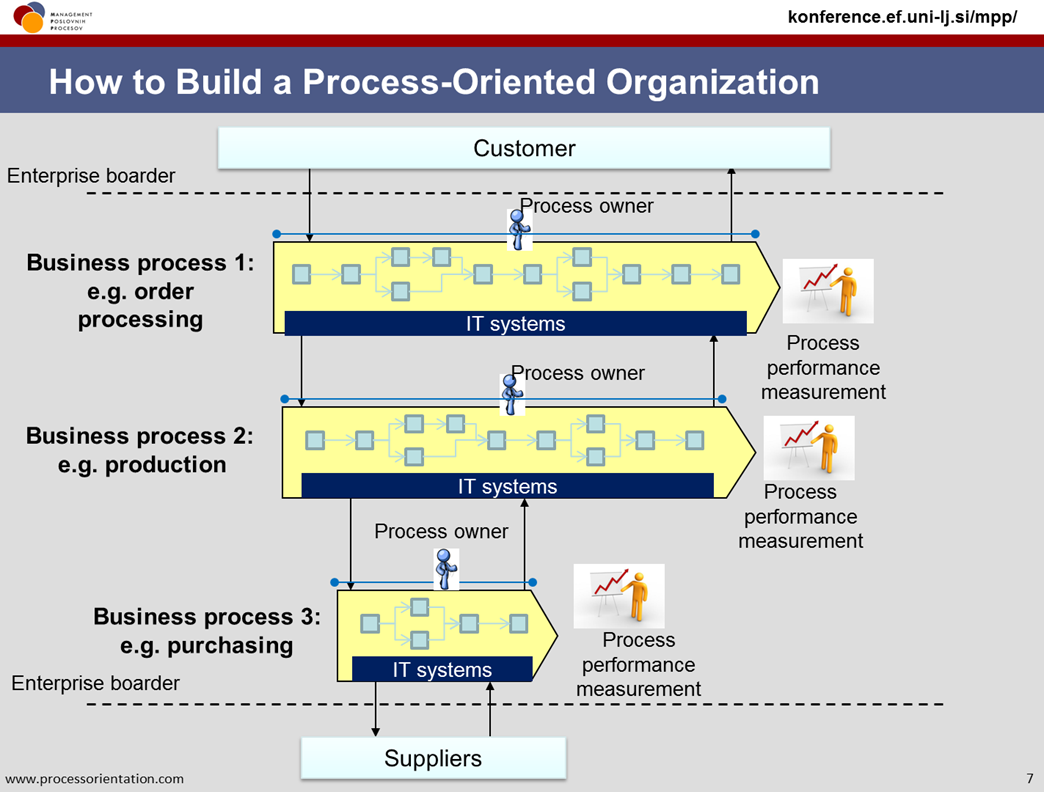

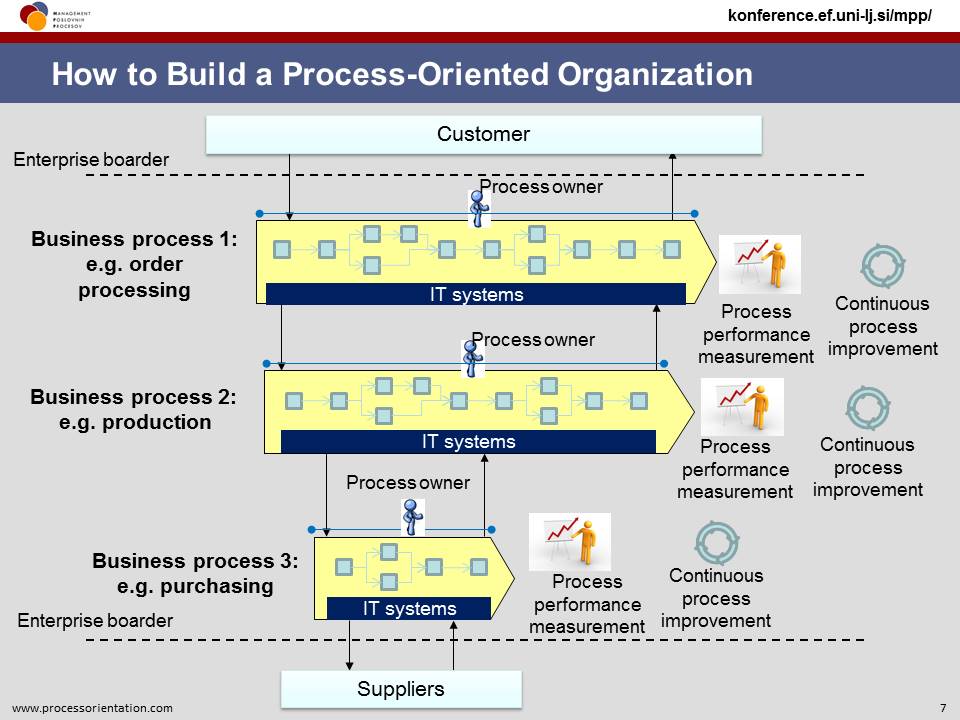

- Process management (capabilitiy to design and manage product and service processes, growth processes, and support processes).

One of the findings of the empirical study is that the combination of information and analytics, customer focus and process management drives financial performance of manufacturing companies. This means that manufacturing companies need to combine information & analytics capabilities with customer focus and process management capabilities to achieve high financial firm performance.